Multi-Layer And Multi-Pass Operation | Zhouxiang Intelligent Welding Robot

Multi-Layer And Multi-Pass Operation | Zhouxiang Intelligent Welding Robot

Nov 16, 2024

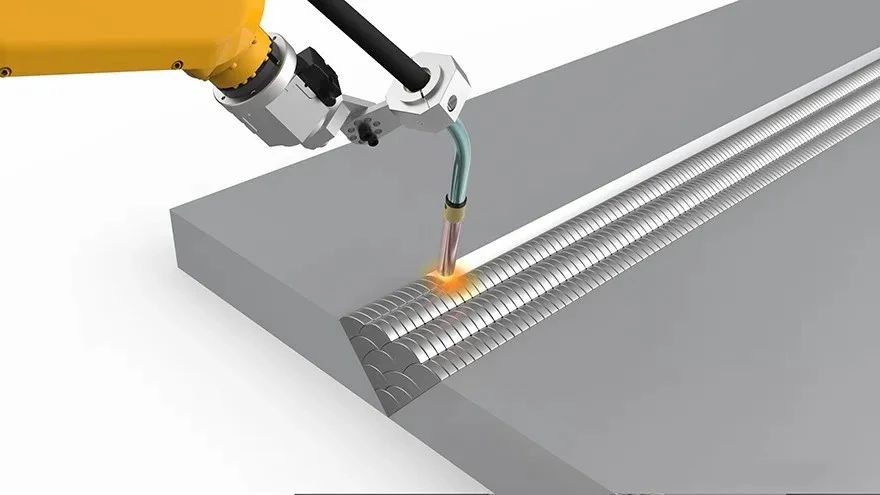

Multi-layer and multi-pass operation

Faced with the challenge of welding medium and thick plates, especially when the plate thickness exceeds the limit of one-time welding and thermal deformation needs to be strictly controlled, multi-layer and multi-pass welding technology came into being and became an effective means to solve this problem.

Multi-layer and multi-pass welding technology uses the high precision and flexibility of the robot arm to accurately execute the welding path and ensure the uniformity and consistency of the weld. Through the preset welding program, the robot can automatically adjust the welding current, welding speed and other parameters to adapt to different materials and welding requirements. This method effectively reduces the residual stress and deformation generated during the welding process by dispersing the welding heat, thereby improving the stability and safety of the welded structure.

Zhouxiang intelligent welding robot matches multi-layer and multi-pass welding processes through model driving. The robot contains a powerful welding process library, groove processes of different plate thicknesses and different angles (including the current, offset, push-pull angle and other parameters of each pass are pre-set in the built process layer in advance). When generating tool paths, different process layers are automatically matched according to different plate thicknesses, and parameters such as offset and current during welding are automatically read. The processing process will execute these parameters to achieve multi-layer and multi-pass welding, realize real-time communication between the robot and the control system, and realize robot weld tracking, weld positioning and other functions.

At present, ship-type welding, flat angle welding, and vertical upward welding can all be achieved in multiple layers and multiple passes, and in the process of multiple layers and multiple passes, it supports welding methods such as sine pendulum, pendulum, L-shaped pendulum and triangular pendulum, supports interruption at the welding hole position and connection at the welding hole position, supports breakpoint positioning for continued processing and setting as breakpoint for continued processing after moving, supports re-arcing and retraction distance, arc return pit filling, gun cleaning and wire cutting, and the welding process and welding direction can be set separately for each pass.

Zhouxiang Enterprise

Specializes in the production of H-beam light and heavy steel production lines, box beam production lines, horizontal production lines, double-joint welding and straightening automatic lines, steel structure robot intelligent workstations, and various intelligent production lines; including CNC flame plasma cutting machines, fiber laser flatbed cutting machines, laser pipe cutting machines, tube-sheet integrated machines, handheld laser welding machines, H-beam assembly machines, gantry submerged arc welding machines, H-beam straightening machines, shot

blasting machines, H-beam assembly welding and straightening integrated machines, welding special machines, auxiliary machines, etc.

Zhouxiang manufacturing, professional quality, high precision, high speed.

Leading technology, stable quality, products are sold well at home and abroad.