T Beam Assembly Welding Machine

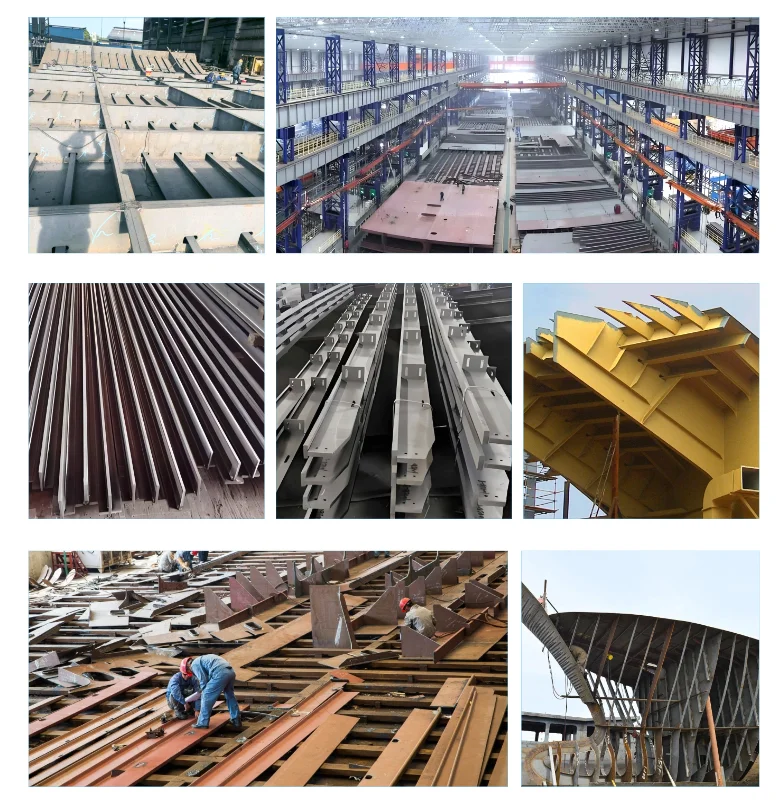

The equipment uses digital intelligent automation technology to accurately transport the panels, webs and other components of the T-profile to the assembly position, and uses auxiliary equipment such as positioning devices and clamping devices to ensure the precise alignment and firm combination of each component during the assembly process, and finally starts welding. The equipment consists of an input roller conveyor, aT-beam assembly machine,an output roller conveyor, an RGV removal trolley, a bracket, a hydraulic system, an electric control system and a welding power supply. Both the central and offset T-beams of the web can be assembled and welded.

| Technical Parameters | |

| Web height(H) | 200~1200mm |

| Webthickness(T1) | 8~25mm |

| Panel width(B) | 90~400mm |

| Panelthickness(T2) | 10~30mm |

| Profile length |

3000~15000mm

|

| TZH-0512 is light duty T-beam assembly welding machine,Different configurations have different prices | |