T Beam Chamfering Grinding Machine

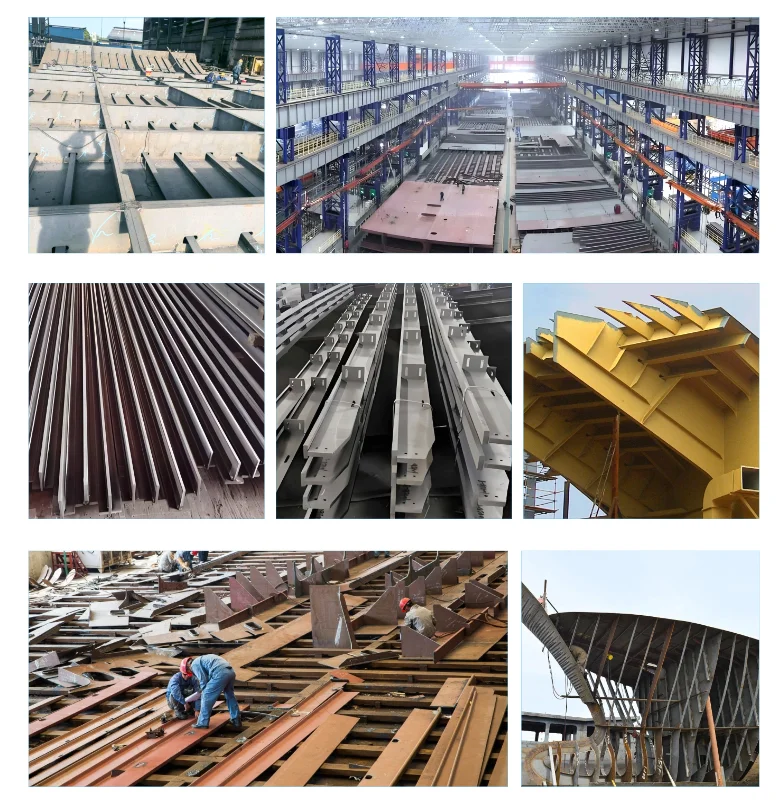

T beam chamfering grinding machine is a mechanical device used for chamfering and grinding the edges of T-beams. It consists of an input driving roller conveyor, alignment device, tool setting mechanism, chamfering host, grinding device, output driving roller conveyor, hydraulic system, and electrical control system. Through process integration and digital intelligence upgrades, this equipment optimizes processing efficiency, space utilization, and quality consistency, making it particularly suitable for highprecision, large-volume panel processing scenarios such as shipbuilding.

| Technical Parameters | |

| Panel width | 90~400mm |

| Panelthickness | 12~30mm |

| Profile length | 4000~15000mm |

Products Description